Gearbox Components and Parts: Everything You Need to Know

Gearbox Parts and Component inventory.

Gearbox parts contain

gear train, or a mechanical unit or component consisting of a series of integrated gears within a housing. In the most basic sense, a gearbox functions like any system of gears; it alters

torque and speed between a driving device like a motor and a load. To know how a gearbox operates, it is necessary to understand the gearbox components and functions. In this article, we will discuss the gearbox components and parts.

Main gearbox parts and components

- Clutch shaft

- Counter shaft

- Main shaft

- Gears

- Bearings

The main gearbox spare parts list is described below.

Clutch shaft

A Clutch shaft or driving shaft is a shaft that takes power from the engine to further supply to other shafts. As the name suggests, the driving shaft is connected via a clutch and when the clutch is engaged, the driving shaft also rotates. The clutch shaft has only one gear fixed on it and it rotates at the same speed as the engine crankshaft.

Counter shaft

A counter shaft is a shaft that connects with the clutch shaft directly. It contains the gear which connects it to the clutch shaft as well as the main shaft. It may be run at the engine speed or at lower than engine speed according to gear ratio.

Main shaft

It is the shaft that runs at the vehicle’s speed. It carries power from the counter shaft by use of gears and according to the gear ratio, it runs at different speeds and torque compared to the counter shaft. One end of this shaft is connected with the universal shaft.

Gears

Gears are used to transmit power from one shaft to another. The amount of torque transmitted via gears depends on the number of teeth and size of the gear. Higher the gear ratio, higher the torque/acceleration, and lesser the speed. All the gears are fixed on their respective shafts except the ones on the main shaft; they can slide into either direction along the shaft.

Bearings

Whenever the rotary motion encounters, bearings are required to support the revolving part and reduce the friction. In the gearbox, both the counter and main shaft are supported by the bearing.

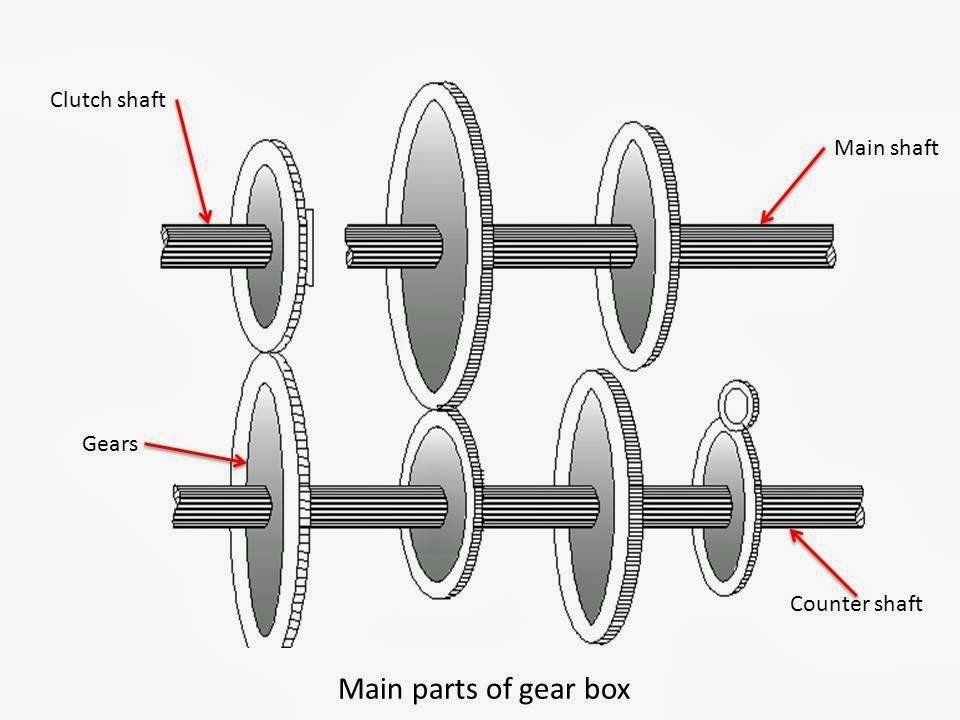

Gearbox parts diagram

In a gearbox, the counter shaft is mashed to the clutch with the use of a couple of gears. So the counter shaft is always in running condition. When the counter shaft is brought in contact with the main shaft by use of meshing gears, the main shaft starts to rotate according to the gear ratio.

When the driver wants to change the gear ratio, simply press the clutch pedal which disconnects the counter shaft with the engine and connects the main shaft with the counter shaft by another gear ratio by use of the gearshift lever.

The diagram of the industrial gearbox components is shown in the figure below.